How is Rockwool produced?

Details

How is Rockwool produced?

Rockwool mineral wool's soundproofing and insulating ability is superior to many other materials. When the process of heat and sound transfer takes place, these radiations are absorbed and penetrate the rock wool fibers.

Rockwool mineral wool's soundproofing and insulating ability is superior to many other materials. When the process of heat and sound transfer takes place, these radiations are absorbed and penetrate the rock wool fibers.

The transmitted radiation will be "captured" by the wool fibers of the mineral wool insulation, so the negative heat absorption process is almost absolute and there is little convection.

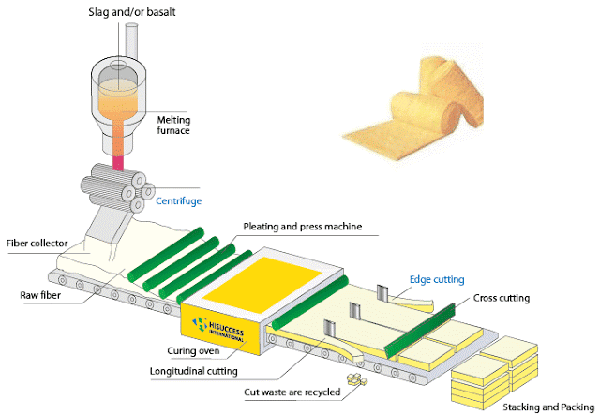

Rockwool mineral wool production process: Rockwool cotton production process, is produced according to a quite complex chain and strictly complies with industrial standards.

Conclusion: Above we have shared the process of making Rockwool cotton sheets. Hopefully this article has provided you with more knowledge about this superior product.

► You may be interested in: Process of producing heat-resistant ceramic cotton.

The transmitted radiation will be "captured" by the wool fibers of the mineral wool insulation, so the negative heat absorption process is almost absolute and there is little convection.

Rockwool mineral wool production process: Rockwool cotton production process, is produced according to a quite complex chain and strictly complies with industrial standards.

- Step 1: Melt a mixture of Basalt and Dolomite rocks.

- Step 2: Create mineral fibers.

- Step 3: Create Rockwool cotton blocks.

Conclusion: Above we have shared the process of making Rockwool cotton sheets. Hopefully this article has provided you with more knowledge about this superior product.

► You may be interested in: Process of producing heat-resistant ceramic cotton.

Other news

- 9 reasons for MINH QUAN to become a leading supplier of insulation materials (19/07/2023)

- Applications of Fire-Resistant Tarpaulins in Industrial Sectors (22/01/2026)

- Deahan Korean Fabric Flexible Air Duct (22/10/2025)

- Ceramic Fireproof Heat-Resistant Gasket – Comparison with Rubber & Graphite Gaskets (24/09/2025)

- Fireproof Insulation Wool for Industrial Projects (22/09/2025)