Process for producing heat-resistant ceramic cotton.

Details

Process for producing heat-resistant ceramic cotton.

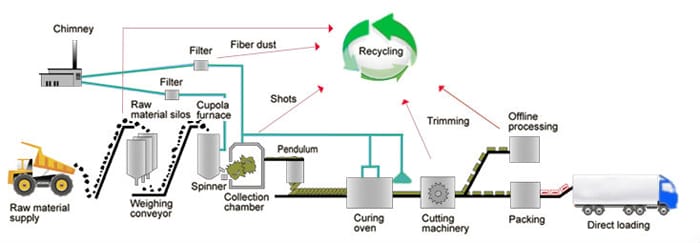

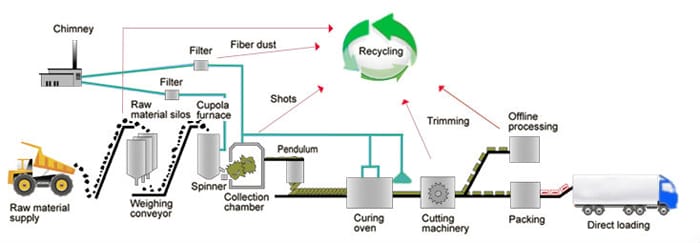

Heat-resistant ceramic wool is produced on a quite complex line and this production process needs to strictly comply with industrial standards

Heat-resistant ceramic wool is produced on a quite complex line and this production process needs to strictly comply with industrial standards.

Product application.

Insulation for furnaces in the cement industry, ceramic industry, metallurgy industry, petrochemical industry, and glass industry. Ceramic cotton production process.

Ceramic cotton production process.

CERAMIC cotton is produced from a continuously operating line, the fibers are woven and woven very firmly, creating a very high tensile force. This type of product does not use glue.

►You may be interested in: Production process of insulating glass wool.

Product application.

Insulation for furnaces in the cement industry, ceramic industry, metallurgy industry, petrochemical industry, and glass industry.

- Fireproof and insulate heat treatment equipment.

- Heat-resistant bricks for aluminum smelting furnaces.

- Insulation for walls, furnace walls and high heat resistant equipment.

CERAMIC cotton is produced from a continuously operating line, the fibers are woven and woven very firmly, creating a very high tensile force. This type of product does not use glue.

- Step 1: Put ingredients into the oven.

- Step 2: Form ceramic fibers.

- Step 3: Form ceramic cotton sheets.

►You may be interested in: Production process of insulating glass wool.

Other news

- 9 reasons for MINH QUAN to become a leading supplier of insulation materials (19/07/2023)

- Applications of Fire-Resistant Tarpaulins in Industrial Sectors (22/01/2026)

- Deahan Korean Fabric Flexible Air Duct (22/10/2025)

- Ceramic Fireproof Heat-Resistant Gasket – Comparison with Rubber & Graphite Gaskets (24/09/2025)

- Fireproof Insulation Wool for Industrial Projects (22/09/2025)